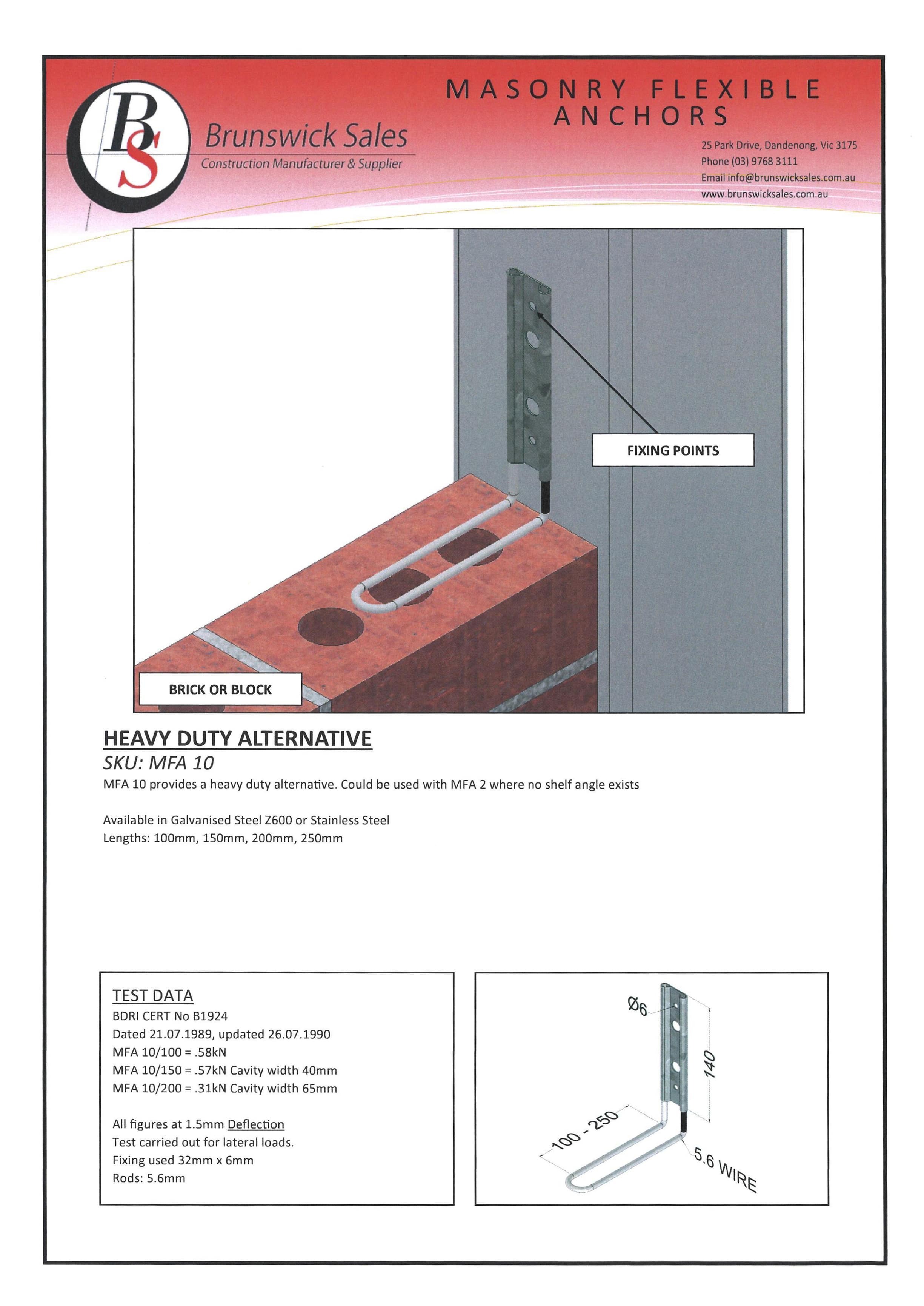

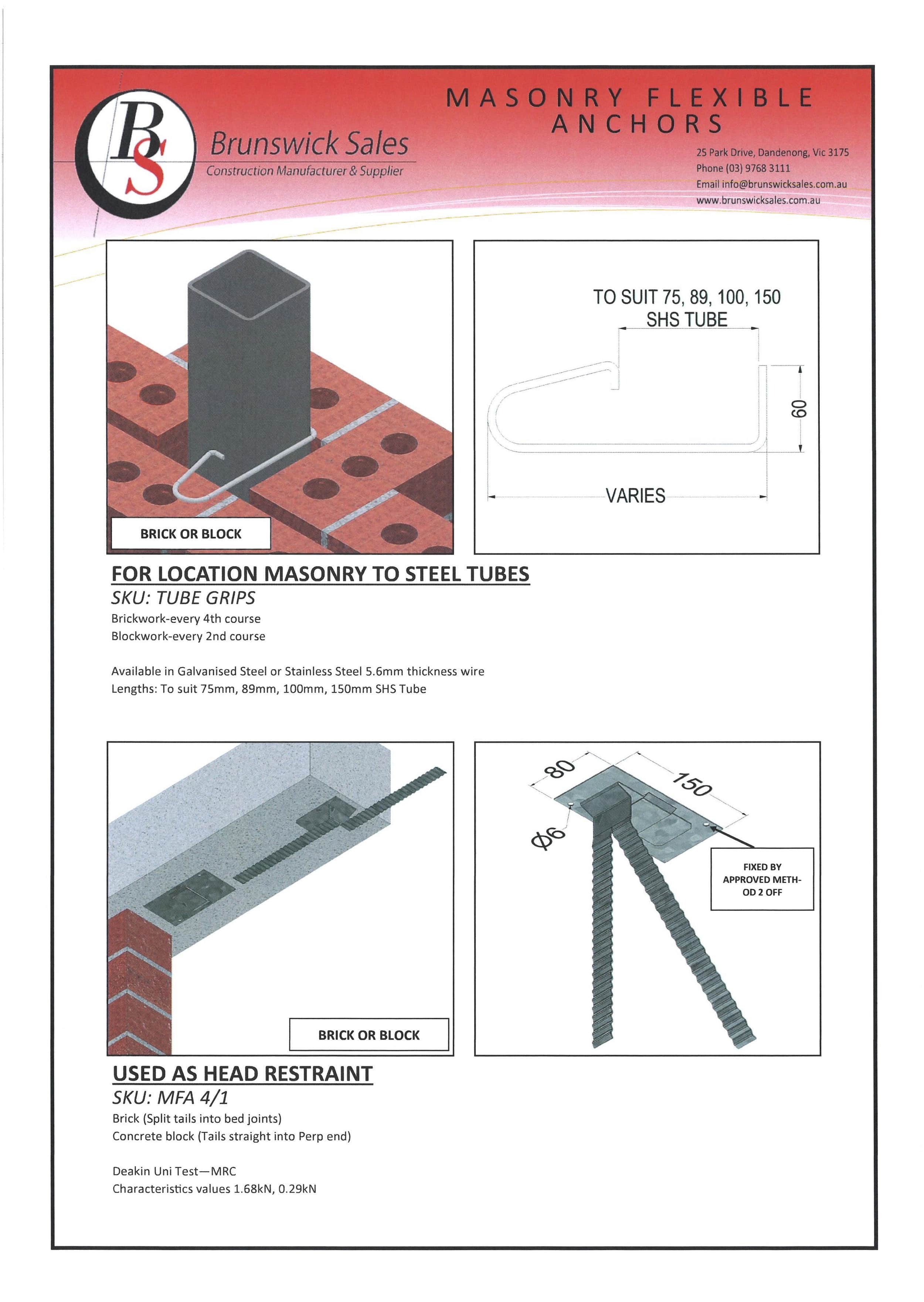

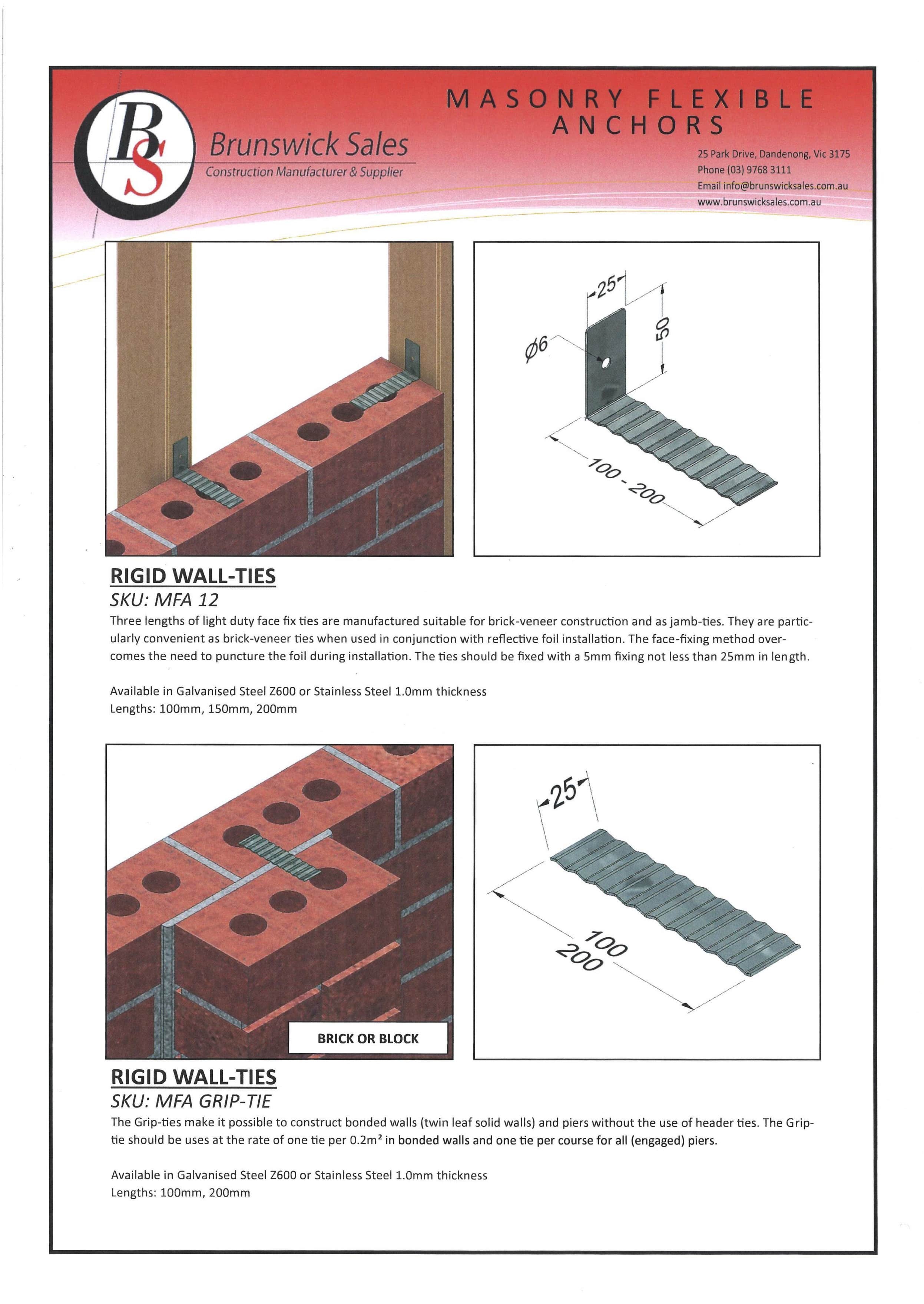

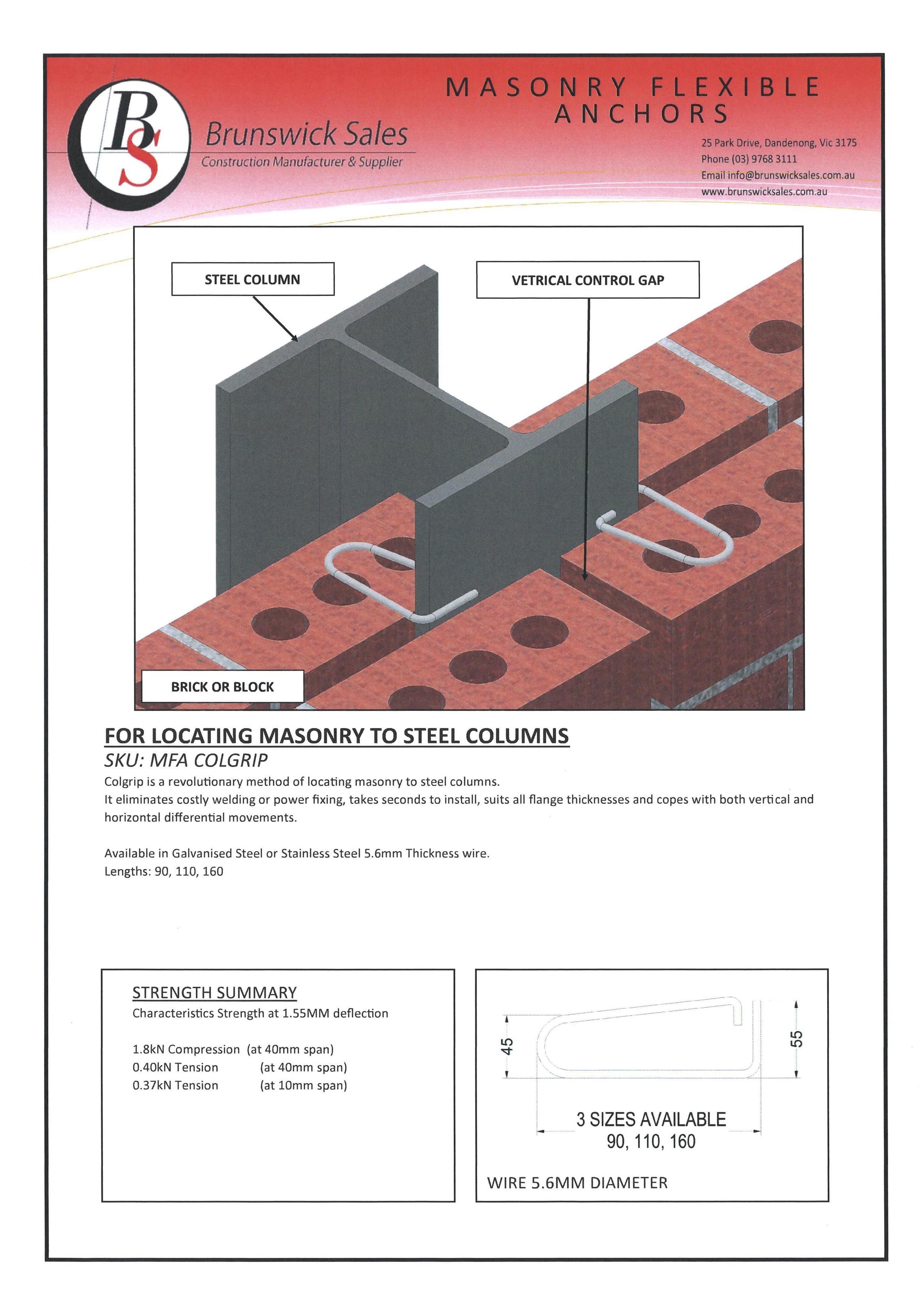

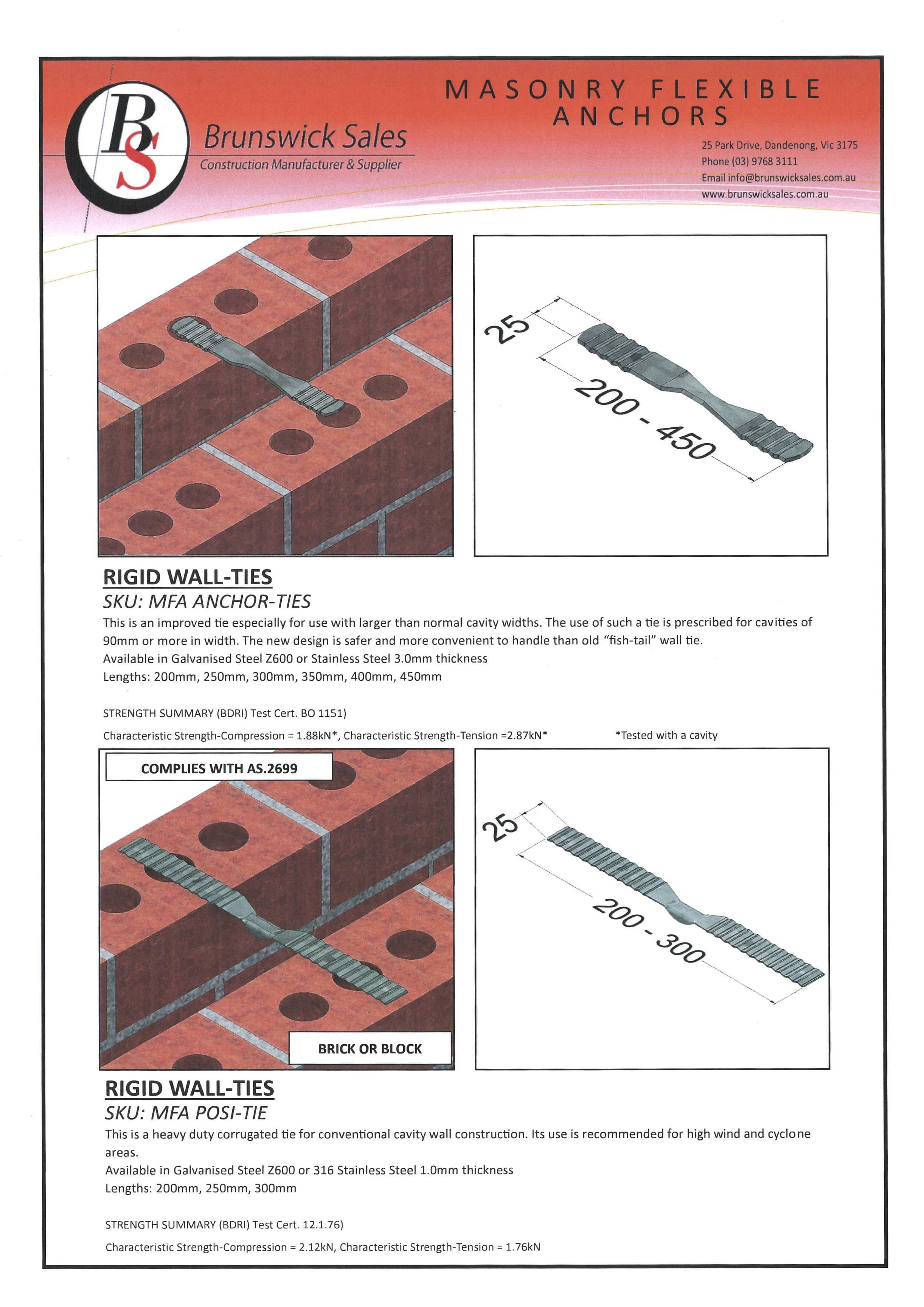

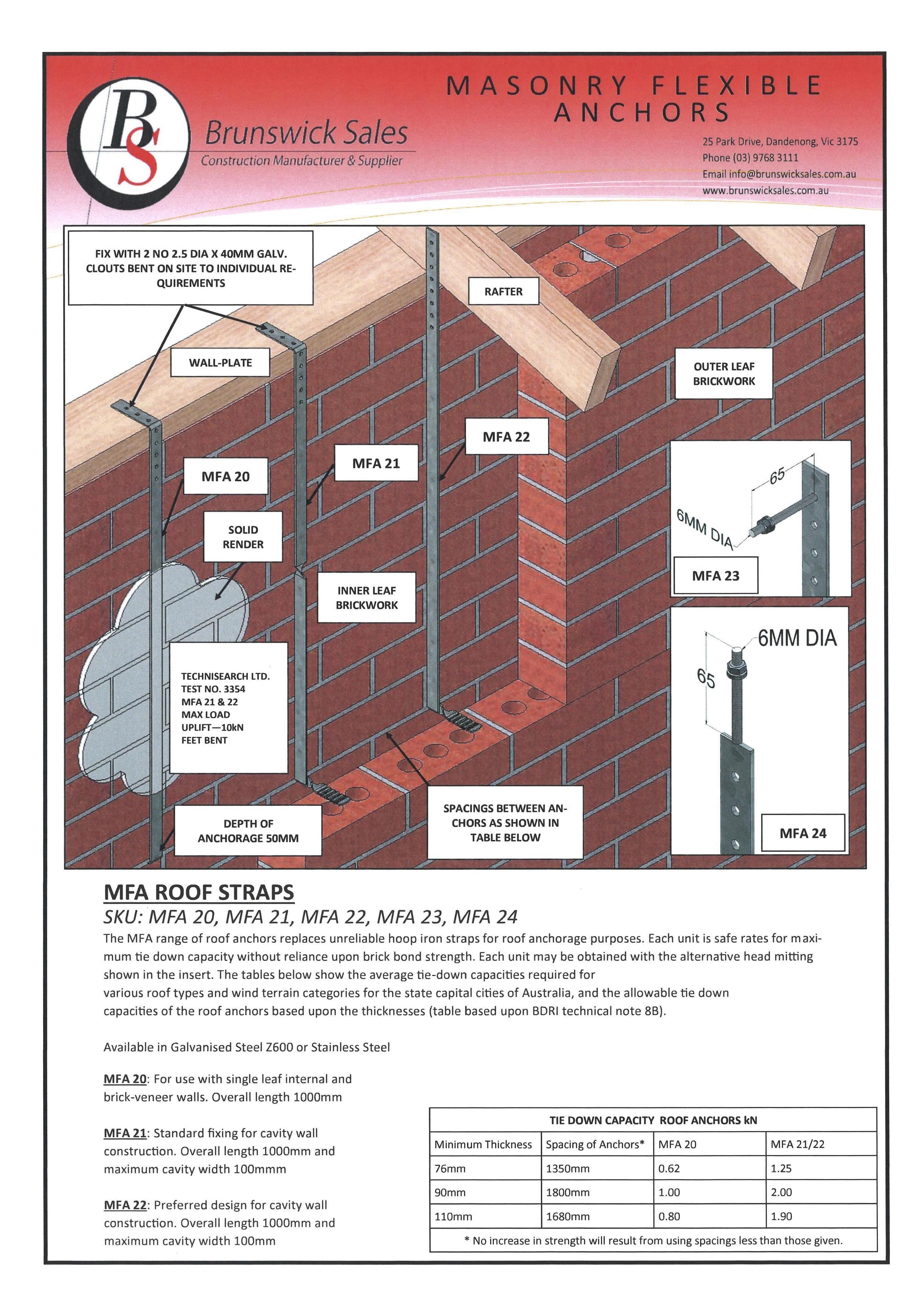

Masonry Flexible Anchors Range

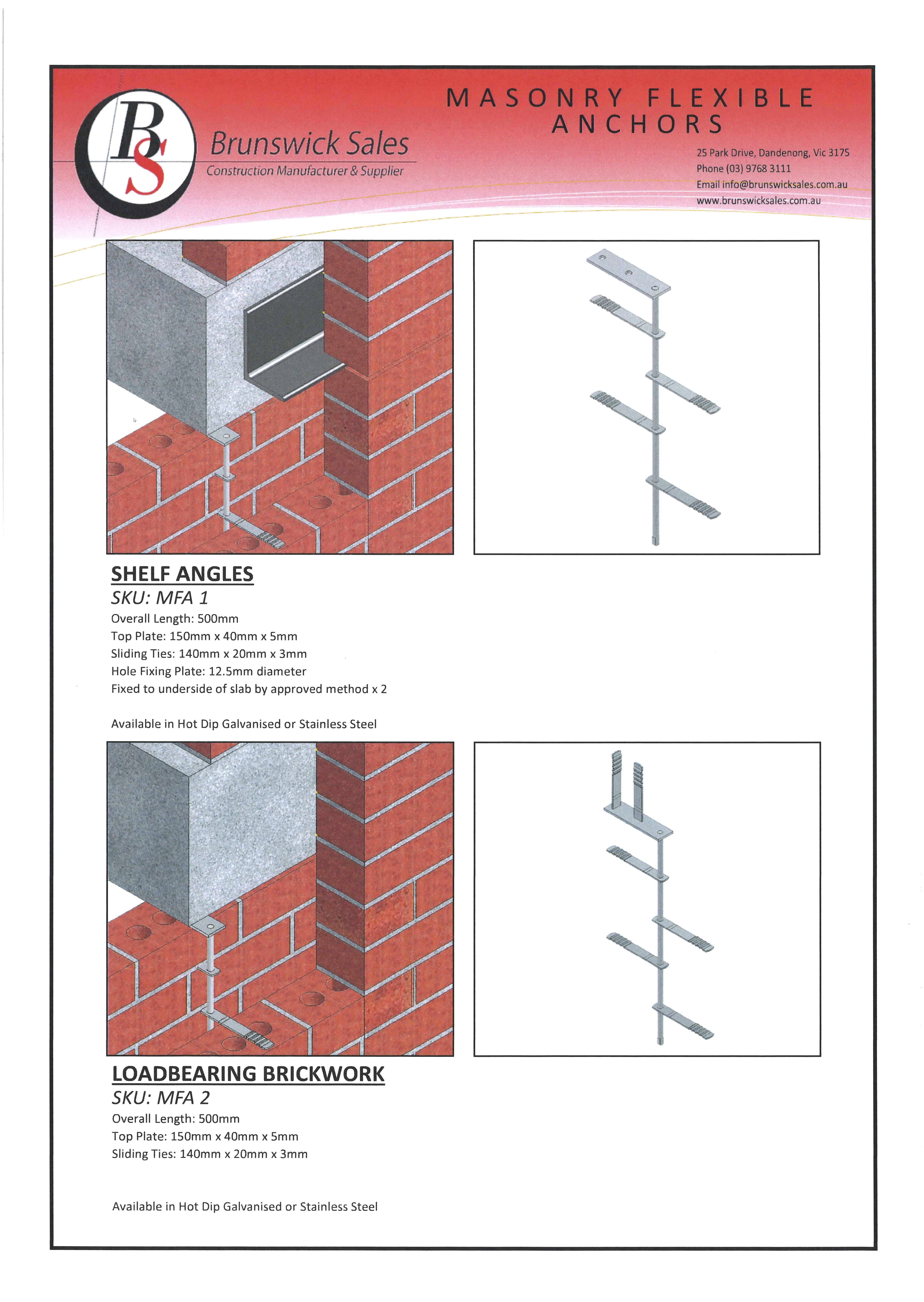

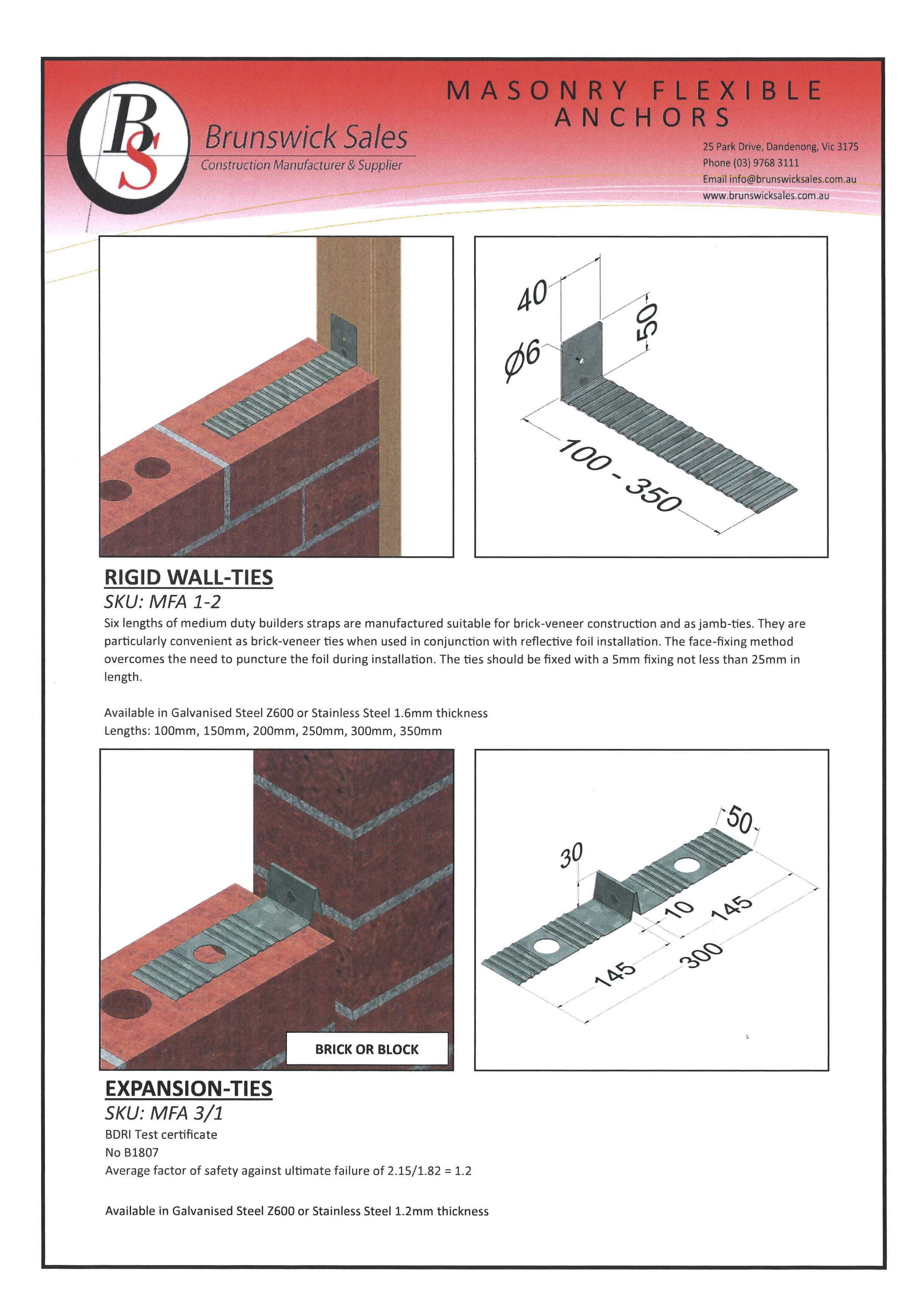

Wherever control gaps are employed the connection between the masonry and the building frame, or separate sections of masonry, must be made with properly manufactured flexible anchors. The structural integrity of masonry will often be primarily dependent upon the adequacy of such anchors. The range of Masonry Flexible Anchors available on this site provides simple solutions to virtually all the control gap situations facing designers.

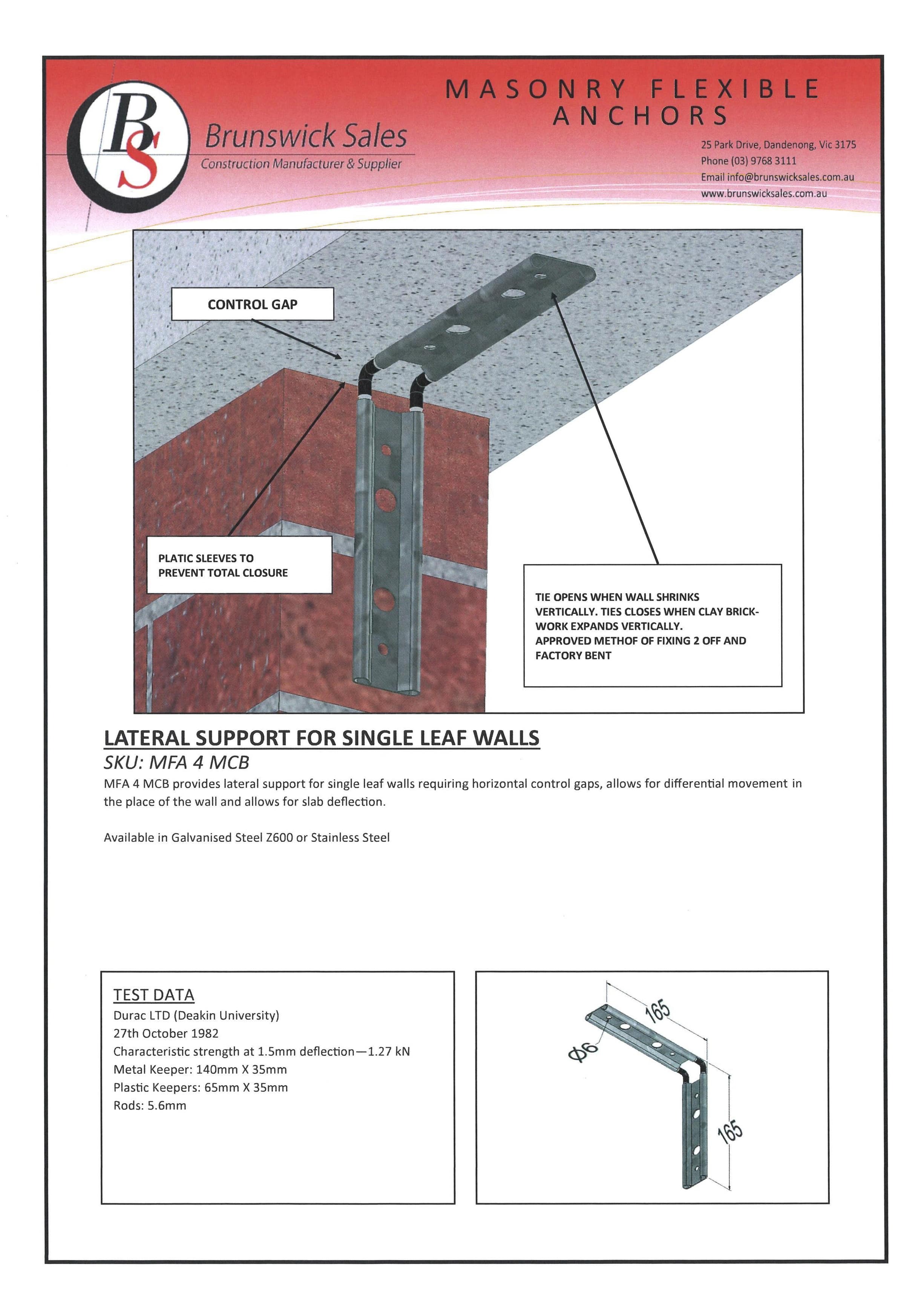

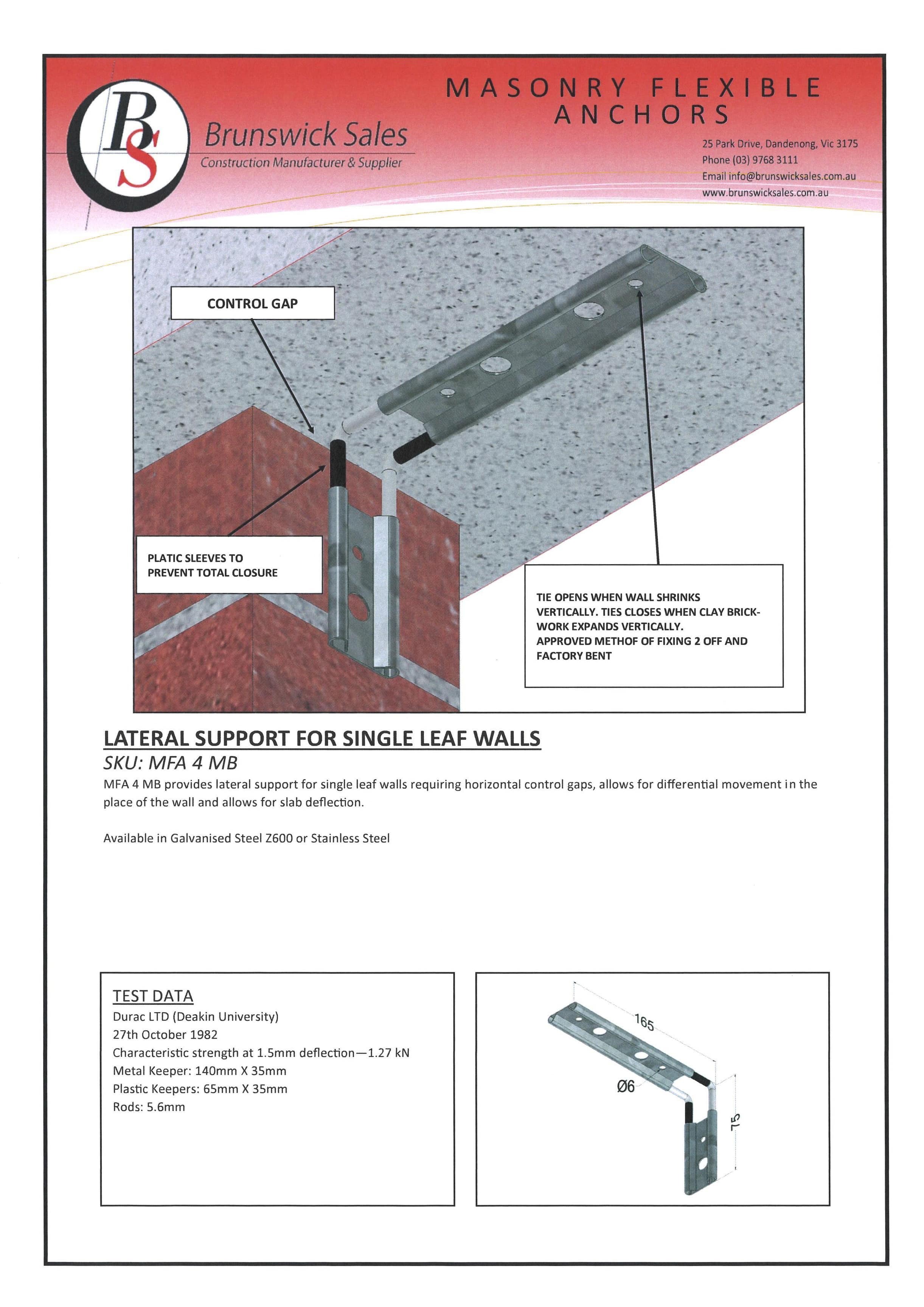

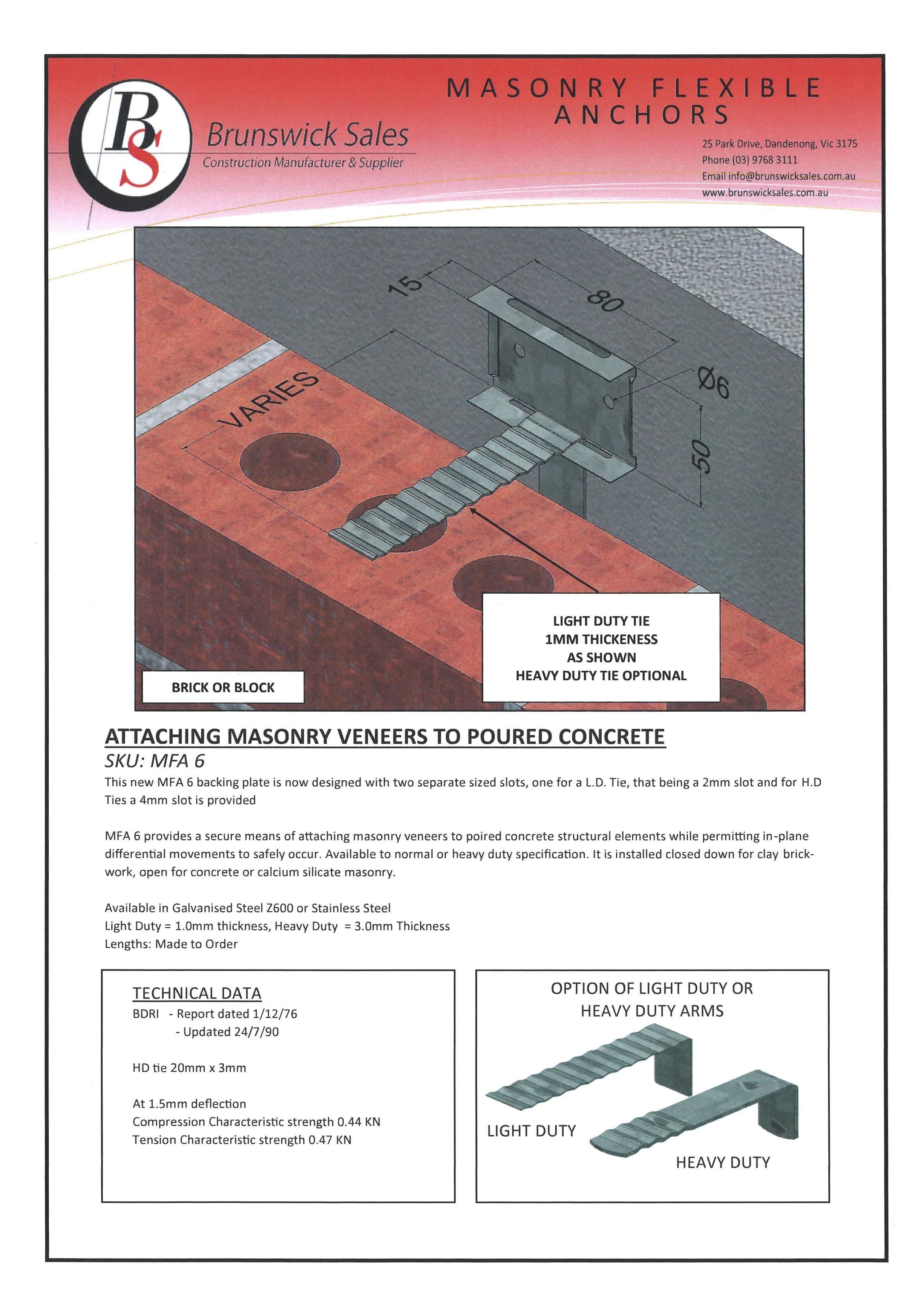

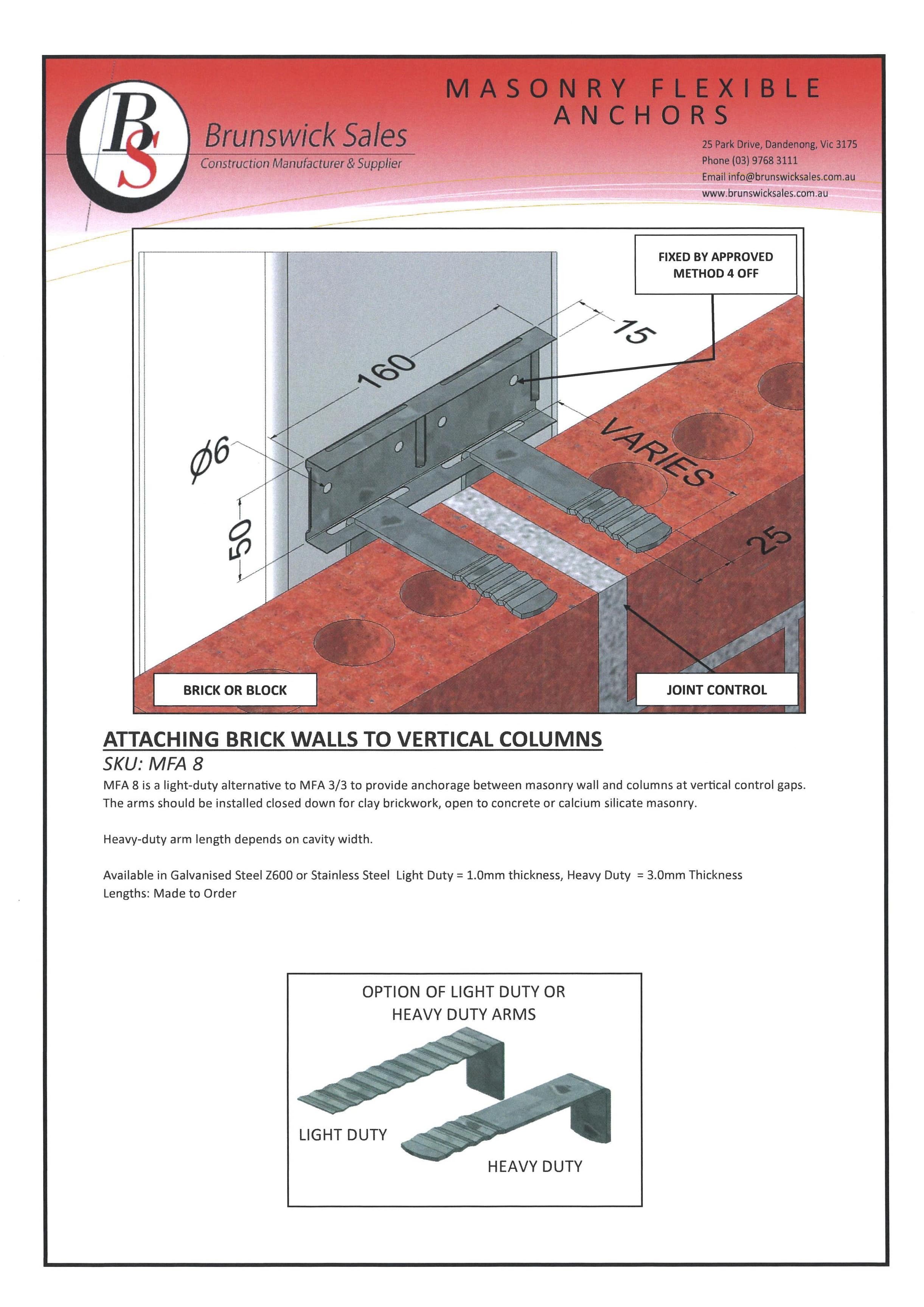

When specifying or otherwise referring to the various designs, it helps all concerned if the products are nominated in terms of their respective MFA numbers.

All products are available in a galvanised finish or grade 316 stainless steel.

Masonry Flexible Anchors

Differential movements in building structure may result from a number of factors:

Permanent changes in the size of the masonry walls

Permanent changes in the size of the masonry walls

Shrinkage of the structure of reinforced concrete buildings

Shrinkage of the structure of reinforced concrete buildings

Elastic deformation of load bearing members

Elastic deformation of load bearing members

Cyclical thermal movements

Cyclical thermal movements

Failure to design for any or all of the above movements can result in considerable structural damage that can be extremely costly and in some instances impracticable to repair.

Buildings that include masonry elements should be designed to accommodate differential movement. The design procedure is relatively simple and Brunswick Sales make a full range of the necessary Masonry Flexible Anchors that will allow masonry structures to be able to cope with this.

Basic Design Factors

Masonry Flexible Anchors (MFA’s) have been developed by Brunswick Sales to provide lateral stability to masonry walls designed to accommodate differential movements.

It is beyond the scope of this page to fully describe the phenomenon of differential movement it should be noted that the movements that must be allowed for can be outlined as follows:

Long term shrinkage of concrete brick and blocks and calcium silicate bricks (both vertically and horizontally)

Long term shrinkage of concrete brick and blocks and calcium silicate bricks (both vertically and horizontally)

Long term expansion of clay bricks (both vertically and horizontally)

Long term expansion of clay bricks (both vertically and horizontally)

Long term vertical shortening of load bearing frames and load bearing walls resulting from such factors as elastic shortening, creep shortening and in the case of reinforced concrete, drying shrinkage

Long term vertical shortening of load bearing frames and load bearing walls resulting from such factors as elastic shortening, creep shortening and in the case of reinforced concrete, drying shrinkage

Long term horizontal shortening of reinforced concrete frames and floors from drying shrinkage

Long term horizontal shortening of reinforced concrete frames and floors from drying shrinkage

Differential thermal movements. The outside cladding of a building is subjected to a greater range of temperature than the internal structure it shields and the effects of this must be considered at the time of design.

Differential thermal movements. The outside cladding of a building is subjected to a greater range of temperature than the internal structure it shields and the effects of this must be considered at the time of design.

Movement in Masonry Walls

The means by which such differential movements can be accommodated is the provision of control gaps (sometimes called expansion gaps or movement joints) between the masonry and the building framework.

Structural requirements in Masonry Walls is usually achieved with the introduction and building in of Wall ties, designed to provide lateral stability and strength when used in correct building practice.

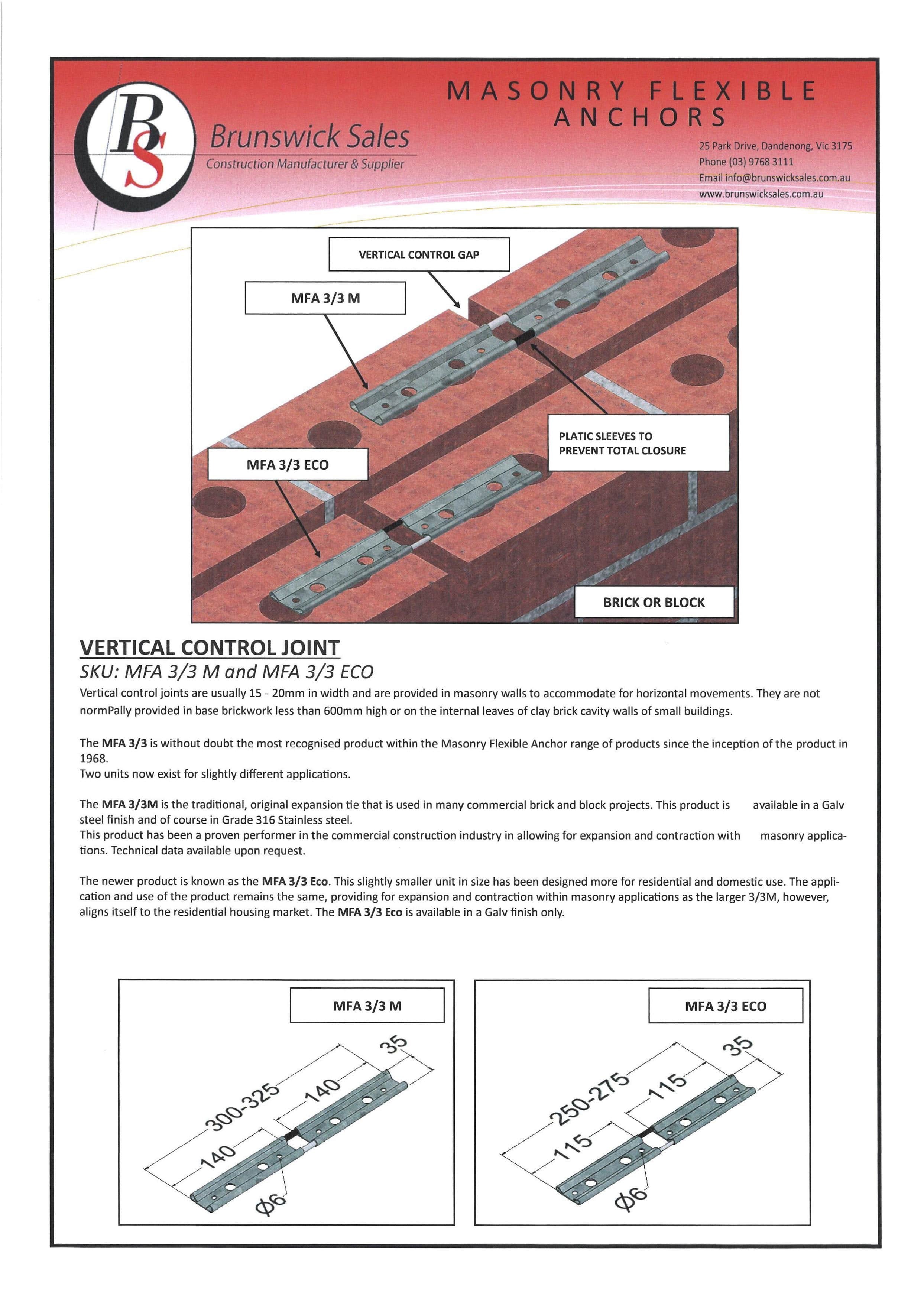

Vertical Control Joints

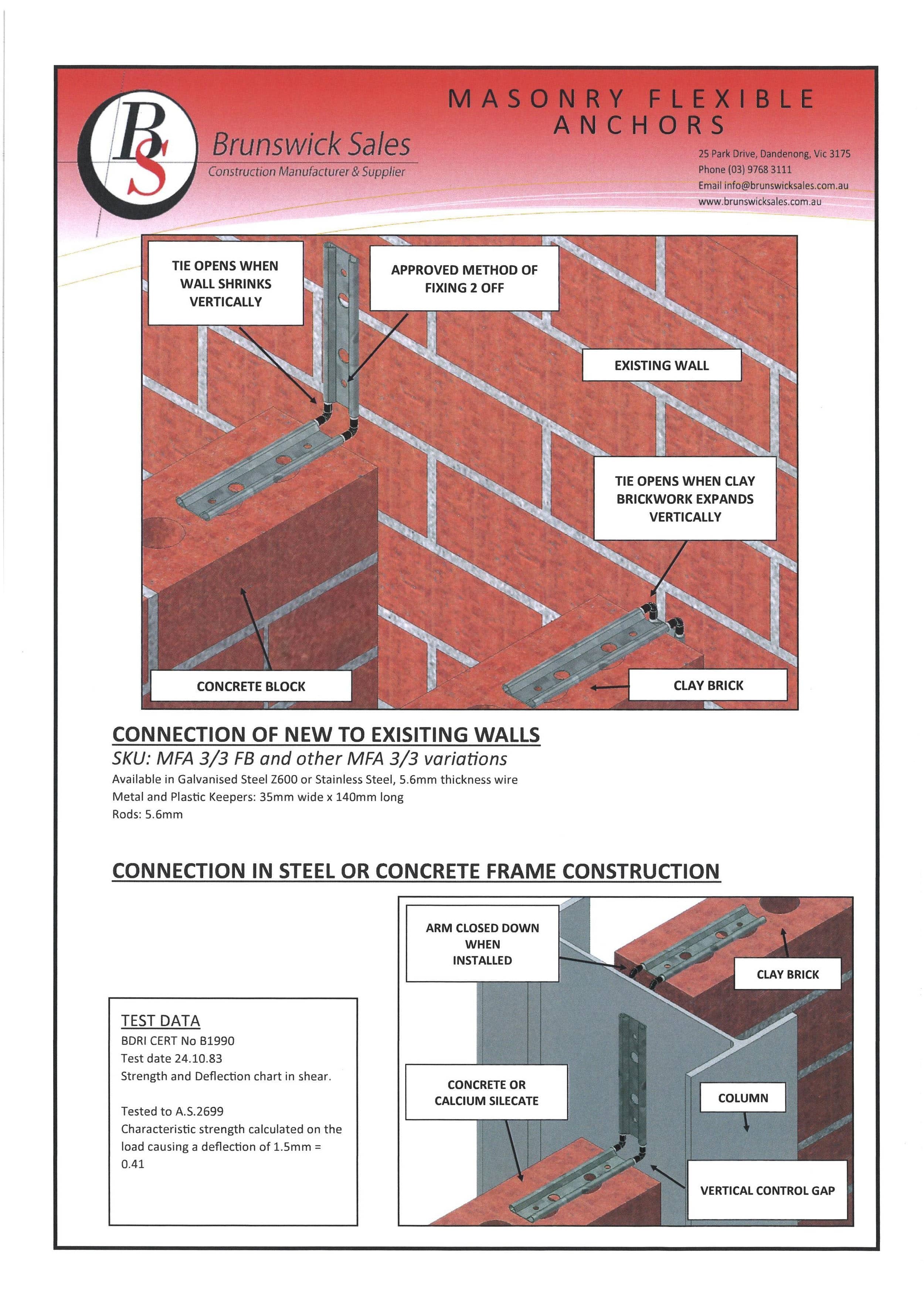

Vertical control gaps, usually 20mm or more in width, are provided in masonry walls to accommodate horizontal movements. They are not normally provided in base brickwork less than 600 mm in height or on the internal leaves of clay brick cavity walls of small buildings. On the other hand, parapets normally require twice the frequency of control gaps than the walls on which they are supported. Vertical control gaps should also be provided at the intersection of concrete and calcium-silicate masonry walls and between virtually all masonry walls and reinforced concrete or steel frames.

Horizontal Control Joints

When clay brickwork is used as cladding or for infill purposes, provision must be made to control the differential vertical movement between the brickwork and the surrounding structure. Horizontal control gaps are usually 10 mm or more in height and spaced to correspond with storey heights.

Contact Us

For detailed product information and inquiries,

please reach out to us directly.